+86 18717921345

(Whatsapp/Wechat)

World-leading provider of boilers and industrial boiler solutions

+86 18717921345|

+86 18717921345| ht@hnhtgf.com|

ht@hnhtgf.com|- Language|

World-leading provider of boilers and industrial boiler solutions

+86 18717921345|

+86 18717921345| ht@hnhtgf.com|

ht@hnhtgf.com|

HUATAI 2025-12-08

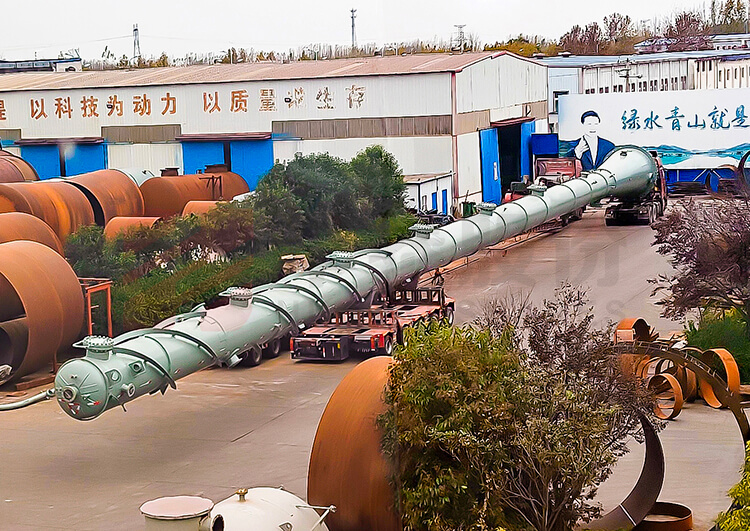

Recently, the propylene recovery tower and azeotropic tower, meticulously developed by Huatai Co., were successfully delivered to the petrochemical industry's 450,000-ton/year integrated light hydrocarbon alcoholization project, providing critical momentum for its smooth advancement.

The two towers delivered this time, as key equipment for the 450,000-ton/year light hydrocarbon alkylation integrated project, include a propylene recovery tower with a diameter of 1.4 meters and a total height of 59.475 meters, along with a azeotropic tower measuring 54 meters in length. From departure at Huatai's production base to final arrival at the project site, the towers were progressed smoothly under the company's coordinated planning and meticulous execution.

During the manufacturing process, the construction of such towers demands high precision, requiring strict accuracy in straightness, cylinder ovality, and internal component gap distances. Leveraging Huatai Co., Ltd.'s profound technical expertise and exquisite manufacturing craftsmanship, the project achieved all dimensional tolerances far exceeding standard specifications through comprehensive precision quality control. This perfectly met all client requirements, demonstrating exceptional manufacturing capabilities.

Since the cooperation was confirmed, Huatai Co., Ltd. promptly established a dedicated project team composed of experienced professionals with extensive collaborative backgrounds. Through seamless coordination, close communication, and rapid response, the team comprehensively considered the tailored process plan and actively overcame multiple challenges in technology, craftsmanship, and timelines. They successfully tackled the difficulties of pre-welded assembly of tower internals, limited operational space, high installation complexity, and tight deadlines. Through full-scale efforts, joint collaboration, and relentless dedication, the entire batch of towers was completed on schedule and with high quality, achieving unified production and transportation.

Additionally, in the logistics process, Huatai shares worked closely with logistics companies to optimize transportation plans multiple times, addressing challenges such as large equipment dimensions and complex manufacturing processes. This ensured safe and efficient transportation, significantly reducing logistics costs for clients. The successful delivery of these two towers not only demonstrates Huatai shares' technical capabilities but also highlights the "hardcore strength" of equipment manufacturing. From the production of core equipment to the implementation of transportation solutions, from tackling technical challenges to coordinating project progress, Huatai shares has continuously broken through in the field of large tower manufacturing with meticulous craftsmanship and bold innovation, providing solid support for the high-quality development of the petrochemical industry.

In the future, Huatai Co., Ltd. will continue to prioritize technological innovation as its core driving force, persistently tackling key technical challenges in the equipment manufacturing sector while expanding its capabilities in large pressure vessel production. Simultaneously, the company will deepen collaborative efforts with industry partners, delivering superior and more efficient equipment solutions to a broader range of enterprises. Steadfastly advancing along the path of pressure vessel manufacturing, Huatai Co., Ltd. will write a remarkable chapter for its future success!

Online chat Inquiry Let’s have a chat about boilers,Feel free to contact us.